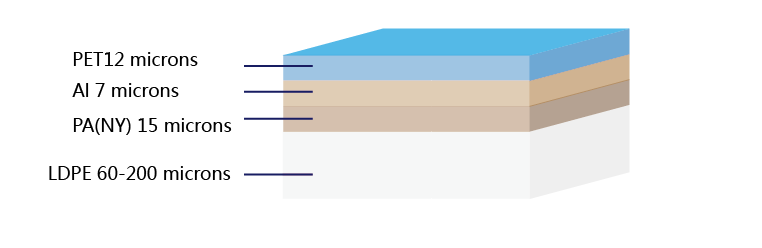

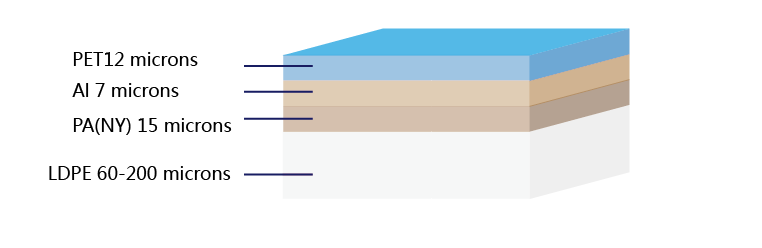

PET12/Al7/PA15/LDPE foil is considered as the most reliable and premium quality laminate when the aluminum foil is applied for multilayer packages. On the other hand, the cost increases accordingly. However, in most cases, the outstanding performance will surely counter the impact of increased cost.

Let’s get into more of it.

- PET12, works as outer print substrate

- Al7, works as barrier layer.

- PA15,a lso knows as Ny15, works as buffer layer between aluminum foil and LDPE film, that makes the final foil more strong, and anti-puncture resistance.

- LDPE film, which can be modified against the products inside, works as inner sealing layer.

Barrier Property

Aluminum foil is considered as the best barrier property aginast OTR and WVTR of all the substate films in flexible packaing industry. So always, an aluminum foil laminate is considered as the best barrier property among all the foil laminates.

However, in actual application, there are factors to be considered to realize a high barrier package. Take alcohole for example, the alcohole molecular is very easy to penetrate through LDPE film, and will destroy the adhesive bwtween the aluminum foil and LDPE film, which furthermore will cause the bonding strength to deteriorate. When the aluminum foil peels off the LDPE film layer, tiny holes may be very easy to appear under wrinkle or rub forces.

On one hand, the improvement of barrier property on LDPE film against alcohol is essential, and on the other hand, an extra PA film applied may apparently improve the performance of this package.

Foil Strength

PET12/Al7/PA15/LDPE is considered to have the premium mechanical strength, with fine materials and reasonable structure.

- PET film, with great mechanical strength ,and good stability, works as print substrate and outside protection.

- Aluminum foil, trapped between PET film and PA film, both are of great mechanical strength.

- PA film, with good anti-puncture performance, that will prevent the inside products to puncture the package. and also PA film will work as buffer layer for aluminum foil and LDPE film, that avoid de-lamination.

- LDPE film, which can be modified against the products inside, works as inner sealing layer.

Anti-puncture property

This foil laminate is enabled with great anti-puncture ability with PA film trapped inside, that will avoid unexpected damage to the package itself. Take spout doypack for example, when the spout doypack is filled in the customer plant, the spout, which have a shapr edge, may bend against the doypack. In some cases, if the doypack is not of good anti-puncture property, the doypack may break.

and, this PET12/Al7/PA15/LDPE foil laminate can be well intended for this filling operation.

When the products is sharp with bones, or rigid stick objects, this PET12/Al7/PA15/LDPE foil laminate is able to protect the package from being punctured through by the products.

so that’s why we always choose this foil laminate for the products that requires premium quality packages. The property really worths the price.

Reach us for a prompt quote if you have any inquiries.

Do you have available rollform aluminum foil description: film composition: PET12/ALUM7PE60 / bag size: 260mm x 500meters / thickness: 79mic. If you have available,how much and is there a minimum order requirements?

All LDPE or HTPE available in market By promoting sustainable practices and supporting companies like Raw tech trade we can make a positive impact on our planet and pave the way towards a more sustainable future.

PET12/AL7/NY15/PE140 QUE MATERIAL PREDOMINA

PET12/AL7/NY15/PE140 QUE MATERIAL PREDOMINA para determinar la partida arancelaria y no este restringida en BOLIVIA