Metallized film has been widely used for coffee packaging in many markets, such as restaurants, offices and household packs. Most of these packages are presented in standup pouches and small sachets mainly intended for instant coffee.

so some customers may wonder, what is metallized film? Is it safe with my coffee products? How does it perform? Should I use metallized film for my coffee products?

Let’s give a short explain.

metallized film, is to deposit a thin layer of aluminum onto the surface of plastic film, that is able to realize bright metallic effect, as below

There are some variations for metallized film, such as Metallized Polyeter film, Metallized Oriented Polypropylene film, Metallized Casted Polyproyplene film, Metallized Nylon film, Metallized PVC film, Metallized Polyurethane film, and metallized paper products, etc, however, when it comes to metallized film in coffee packaging, people usually mean metallized polyeter film(short as VMPET Film) . Let’s get further into it.

VMPET film are perffered with below excellent properties.

- High barrier property against moisture and oxygen

- Flavor protection

- Sunlight shielding

- Vivid print

- Lower Cost

High Barrier Property

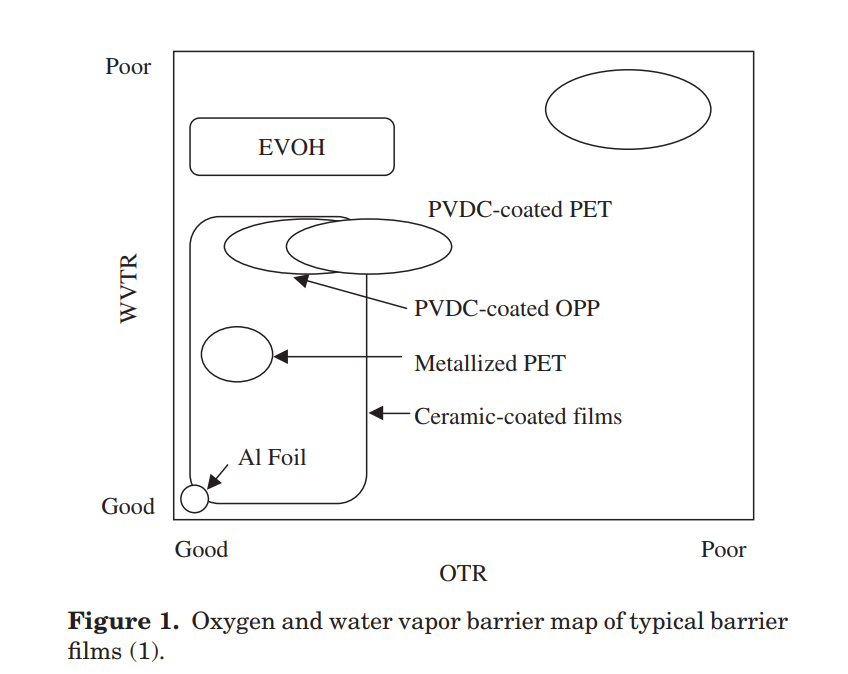

As you can observe from the above graphic art, the barrier property for metallized PET is only worse than aluminum foil and premium quality ceramic-coated film, the data of water vapor transmission rate (WVTR) and Oxygen transmission rate (OTR) we use is as below.

| Items | Value |

| WVTR | |

| OTR |

You may download the specification for our metallized PET film for further understanding.

Flavor Protection

The final coffee package will have to be great flavor protection for the inside products, and mainly this function is achieved with metallized PET film, however, metallized PET film never work alone to realize the protection package, most common structure as below.

- PET/VMPET/LDPE

- BOPPVMPET/LDPE

- Matte BOPP/VMPET/LDPE

Each structure with different properties that will be explained in future posts.

Sunlight Shielding

Long exposure of coffee beans to sunlight will deteriorate the flavor and smelling, so the final package will not be able to see through with VMPET film trapped between the multilayers.

Solid and Vivid Print

VMPET is bright metallic effect, that is able to reflect the light, that will make the final package print much more solid and vivid.

As you can see, the foil structure for left package is PET/LDPE, however the right package is MatteBOPP/VMPET/LDPE. With an extra VMPET layer, the print will just present in another visual effect. This will help to improve the quality level for the final coffee products, and that’s why more and more customer prefer a VMPET layer in their packages.

Lower Cost

Compared to coffee bags with aluminum foil, metallized film coffee bags are of much lower cost, as the cost of metallized PET film is only 1/2~1/3 of the aluminum foil price.

However, the true fact is, the barrier property for metallized PET film is never as good as aluminum foil, and the bags finalized with aluminum foil is also more quality than metallized film bags. We will give a further analysis on metallized film VS aluminum foil for coffee packaging.