A good package should tell and sale well. Here at Tongli, we try our best to manufacture gorgeous bags for the coffeee roasters, which not only provide the essential preservation for the products, but also increase the branding and sales revenue in a steady way. Here, we are going to share some of our experience of our QC work.

Our sensitivity to the hygiene conditions in our manufacturing plant enables us stretching in a long road to finalize packages in a very expected way, and also explore the most potential of the materials in the produce craftsmanship. We always believe, a clean environment would be the very starting point of our business. So, we are doing our best to create a fine and elegant environment for the mutual long-term development for the customers and us.

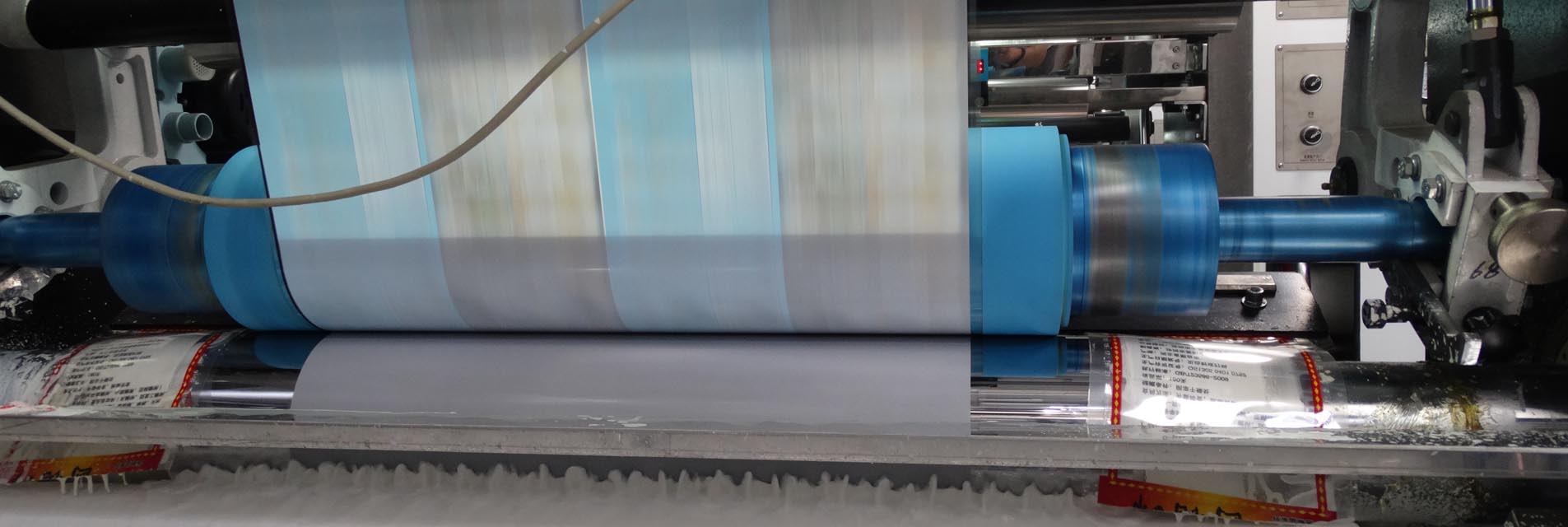

It is our fundamental job to finalize the artwork design of our customers into the printed package with the highest color fidelity, and stay consistent during all the future reprint. Honestly speaking, that is very challenging job as color is so verstile and enfluenced by so many factors even from the different people viewing them. We are facing the challenge for 13 years, and have been doing our work step by step, and try to revert with these customers a reliable and trustworthy print service in the long run.

Bag making, actually, is not less than a sculpture work that turns the common film materials into an outstanding wedding dress for the inside value products. It needs high skills, enough patience, and most importantly, the scrupulous altitude. We attend to each order produce in our plant as it is like a new baby. We take it seriously and gently. We would likve to work it into an art.

After excellent printing and delicate bag-making, there should be a gorgeous appearance achieved on the final coffee bag. Here, we have a standard to evaluate a fine surface, which should eliminate the contamination, wrinkles, scratch lines, hidden damage, etc.

The freshness of the newly roasted coffee should be kept inside the package for a prolonged time for the distribution progress. That will not only be decided by the film materials used for the coffee bag, but also the treatment at customer place and storage conditions. For the bag itself, we would like to adapt first grade materials to achieve a great bag of high barrier performance, keeping the freshness inside as long as possible.

The bag, under any circumstances, should be a great protection for the products from filling to distribution, and the time when the products are in the hands of the consumers. We take several measures to test the bag strength in our daily QA work, and here we are going to share some of our experience in doing this work.

The valve should work well when coffee is filled into the bag, otherwise the coffee bag may be expanded into a fatty freak as of carbon dioxide inflation a few days after the filling process. On one hand, we take effective measures to low the bad rates of the degassing valve, and on the other hand, we ensure the valve well welded to the bag.

The coffee bag should be easily torn in the hands of the consumers. We put this into a daily check in our QA work. Here, we are going to share some of our QA experience ,and bad cases in our orders.

We are all humans, and of course, we will never eliminate each and every of the mistakes in our order produce. Indeed, we have a reliable and evolutionary system to reduce the rates of mistakes.Manufacturing recording system is one of the knowledge to enable us trace back to most of the problems.

Laboratory tests are essential to keep us updated with the intrinsic property of the foil mateirals which are not visible to the human eyes. Here, we are going to share some of the common tests under our laboratory conditions.

There will be a QC & Test report released against each and every of the order produced, against the requirement of the customers. This proves to be an effective way to revert the order to the customers. Here, we are going to share some of our experiences regarding this report.

Third parties can be entrusted by the customer to perform inspection and tests against the agreed standard, like EC and FDA regulations., to ensure conformity.

Here, we are going to share some of the third parties executed on our previous orders.

Facing the challenges of global chemical polutions from the sky to earth, from the underearth water to the sea, it is now quite emergent for the human to achieve a better sustainable packaging based on mono material recycle system or compostable film materials.

Actually, our company is moving a steady step toward these eco-friendly packages, and let’s try to create a better sustinable future for all of us humans.