When the bag is made on the bag-making machine, the edges will have to be well sealed to form a final perfect package.

However in actual produce, there may be unexpected accidents that may cause the edges not to tightly sealed, such as small tiny holes left in the sealed edge, that would be an disaster for some liquid products, or products that needs to be well protected against water vapor or oxygen outside the package.

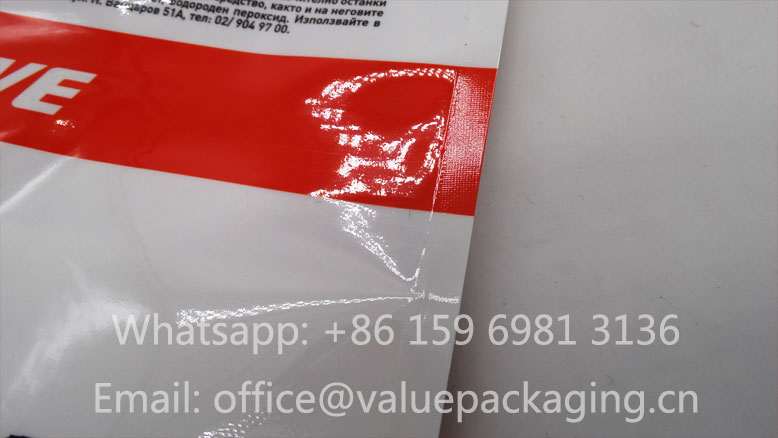

So we usually perform penetration test with dyne coloring agent to check if there is any holes in the sealed edge.

Dyne coloring agent is a chemical substance with colors that can be able to pass through any tiny small holes that exists, so we can rely on this test.

Just watch video for actual test processing.