Coffee packaging will have to be great barrier property and flavor protection for the inside products. When it comes to standup pouch packaging, the most common used barrier film is metallized film (mainly metallized polyeter film) and aluminum foil, and in this article, we are going to have a brief comparison on these two packages.

Metallized film, is to deposit a thin layer of aluminum onto the Polyester film with thickness 12 microns (48 gauge), and finalize a bright metallic film with excellent barrier property, usually short as VMPET Film.

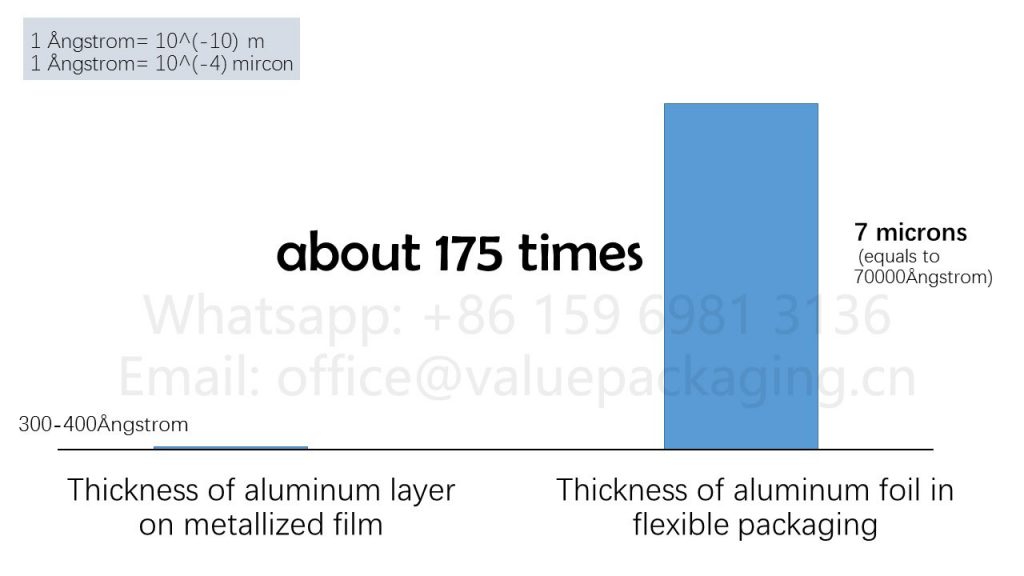

Aluminum foil, is a thin-rolled sheet of aluminum alloy with 7 microns (0.275 mil) that is the mostly used foil in flexible packaging.

Metallized PET film and aluminum foil are both good barrier materials to keep the coffee products fresh as long as possible, we are going to have a further comparison on these two standup pouches below

—Metallized Film Pouch (PET/VMPET/LDPE)

—Aluminum Foil Pouch (PET/AL/LDPE)

Barrier Property

the main reason for their barrier property is the thickness of aluminum. On metallized PET film, there is only a thin depositing aluminum layer with thickness about 300-400 ?ngstrom, that is only about 1/175 of the thickness of aluminum foil, you can observe below graphic.

so you can easily find out, the barrier property of metallized PET film is some worse than aluminum foil, with Water Vapor Transmission Rate (WVTR) and Oxygen Transmission Rate (OTR) in below table.

| Film | OTR (cc/m2,24h) | WVTR (g/m2,24h) |

| Aluminum Foil 7microns | 0 | 0 |

| Metallized PET 12microns | 0.95 | 1.2 |

So, in flexible packaging industry, aluminum foil pouch is considered as the best barrier property of all these multi-layer packages, and intended for longest shelf life for coffee products.

Cost Considerations

However, metallized PET film succeeds in realizing a good barrier film that is suitable for packages that will meet the requirements for most products, it is more cost-effective. The price of metallized PET film is only 1/2~1/3 of the price of aluminum foil 7 microns, so the price for metallized film pouch is lower than aluminum foil pouch.

You can view an exact price evaluation on metallized film pouch and aluminum foil pouch of 12oz coffee bag here.

Stiffness/standup effect

Aluminum foil is thin aluminum metal sheet, and the main body for metallized PET film is plastic polyester film 12 microns. Nevertheless, plastic polyester film is not as stiff and rigid as aluminum foil.

Video of stiffness of VMPET and aluminum foil

So, when these two materials are converted into standup pouches, aluminum foil pouch ( PET/AL/PE ) will be more stiff and rigid than metallized film pouch (PET/VMPET/PE). So, when these two pouches are filled with products, aluminum foil pouch is able to present better standing effect on the shelf.

Sunlight Shielding Ability

The thickness of aluminum on the metallized PET film is so thin that when we pick up a piece of metallized film in front of our eyes, and we look at the sunlight side, we will find out, we can somewhat see through it, although not fully see through. So, metallized film pouch is not so great sunlight shielding as aluminum foil pouch.

Image on see through metallized film

Genearally speaking, aluminum foil pouch is easier to present premium quality packages than metallized film pouch, however, this is not always the case, as different customers may want different package effect for their products, such as hand feeling, matte finish effect, clear window etc, One will have to choose the best package based on his own situation.

Sincerely hope you will get the best package for your coffee products.