Some customers prefer kraft paper bags for their products, as the kraft paper bag is able to present natural flavors to the package and final products. When the customers would like to print their logo and artwork on the kraft paper, there are some points that needs us to pay more attention to realize the best print effect on the final package.

In this post, we are going to share our experience regarding the print work, and hope it be of help for you.

Print on plastic film or on kraft paper

As kraft paper is made of plant fiber, that cause the surface to be coarse with tiny holes. When the print ink is printed on the surface, the ink may penetrate into the tiny holes, which cause the print artwork not to be so solid. However, printing on plastic film is totally different, in which case, the ink will never be absorbed into the film, so usually the ink printed on the plastic film will form a solid ink layer that is about 2 microns thickness in gravure printing.

Usually, when the artwork is directly printed on the kraft paper, it usually has simple colors, like black, or just simple artwork.

Please note, print on coated paper is totally anther thing, like magzine, advertising flyers etc, that is seldom applied in package print.

So, we will print on the plastic film, and then laminate with kraft paper, along with inner sealing layer, and then converted into paper pouches.

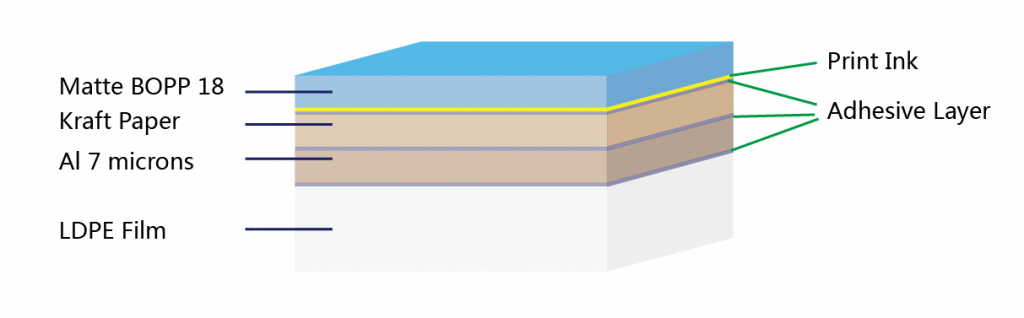

Kraft Paper Foil Structure

The below graphic shows the kraft paper foil structure MatteBOPP18/Kraft Paper/Al7/LDPE which is mostly common used for coffee beans package. Of course, Al 7 micron can be replaced by VMPET 12 Film if you do not require the supreme barrier property, at your choice.

As you can observe, the print ink is trapped between outside Matte BOPP film and Kraft paper, that means the artwork will have to be printed on the inner side of Matte BOPP film, and then further laminate with kraft paper through a layer of adhesive.

Here comes the key point, the ink layer is about 2 microns thick, so is the adhesive layer, however the thickness of kraft paper is about 80~90 microns with porous fibers.

If the print ink layer or adhesive is not dry enough when the printed Matte BOPP film is laminated with kraft paper, there may be risks that the undried ink will partly penetrate into the kraft paper, that means the colors are losing.

Further more, the color of kraft paper is usually brown or some kind of yellowish, if there is colors in the artwork that is close to these colors, there may be risks that the artwork color is not so apparent when printed on a brown kraft paper background. We ever experienced this failure case of our own customer, who finalize a very great artwork design, however when the final package is finished, the expected effect is totally lost.

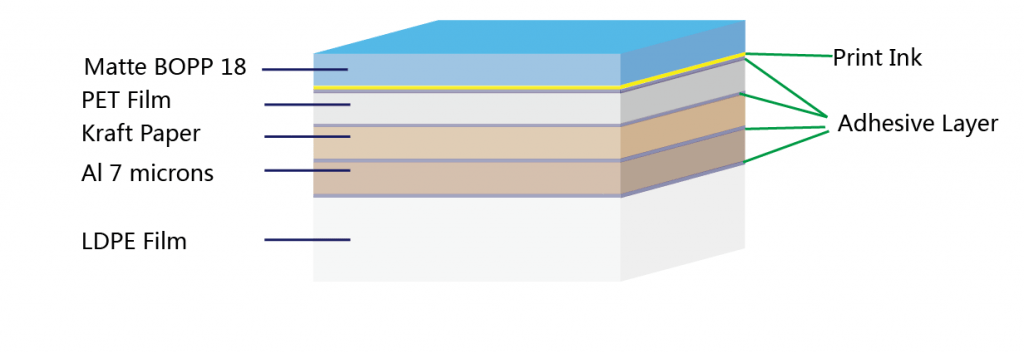

So if the customer would like to persue the most accurate colors for his artwork, we advise to add another bloack layer between Matte BOPP film and kraft paper, and clear PET film is considered as the ideal film material, so the final foil structure should be as below.

Of course, the cost will increase accordingly, and you can reach us for the best price to evaluate the feasibility when you have these needs.