We are making so better and better use of kraft paper in flexible pouch packages

Kraft paper becomes more and more important in our business, with more items developed to meet the various requirements from our customers.

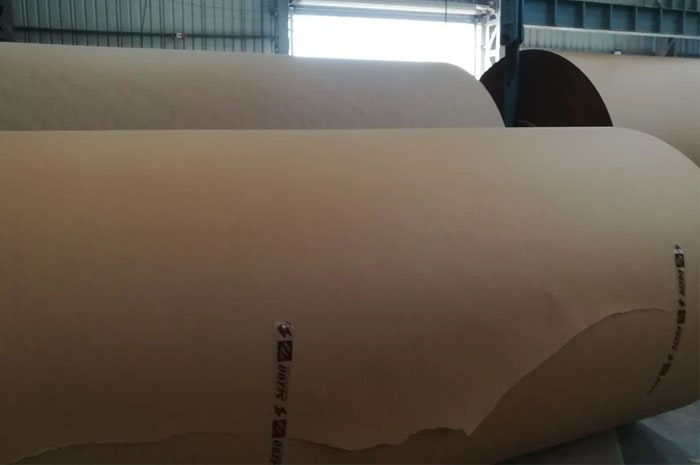

Kraft paper is one of the most common paper materials applied in flexible packaging, which finds applications for various products. It is biodegradable, compostable and fully recyclable. Along with the increasing demand for more sustainable packages, kraft paper becomes more and more important in the packages. When laminated with other bioplastic film materials, the performance can be reinforced to meet the requirments of various products.

Here, in this post, we are going to guide our customers with a better understanding on kraft paper, and try to assist the customers to achieve the expected sustainable packages for their lovely products.

Kraft paper can be recycled up to seven times before it totally degraded. It not only largely reduce the plastic pollution caused by the traditional fossil-chemical film packages, but also reduce the cost, which makes more products affordable to more people. That’s why kraft paper is playing an important role in packaging since it is born. The paper may be coated with polyethylene to ensure an effective barrier against moisture, grease and bacteria, however recyclability is hindered. Now water-bsed heat seal coating is developed to acheive the sealing of package based on eco-friendly considerations.

Kraft paper becomes more and more important in our business, with more items developed to meet the various requirements from our customers.

Kraft paper is usually made from wood pulp by the kraft process. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. Long fibers in the pulp will provide enough strength to the paper and wet strength chemicals are added to even further improve the strength. Brown and white paper are both produced.

The kraft paper we use will be able to meet the requirements for BRC food certifificate.

We hereby commit our kraft paper will be in compliance with FDA regulations, and thir-party inspection is available on customer’s request.

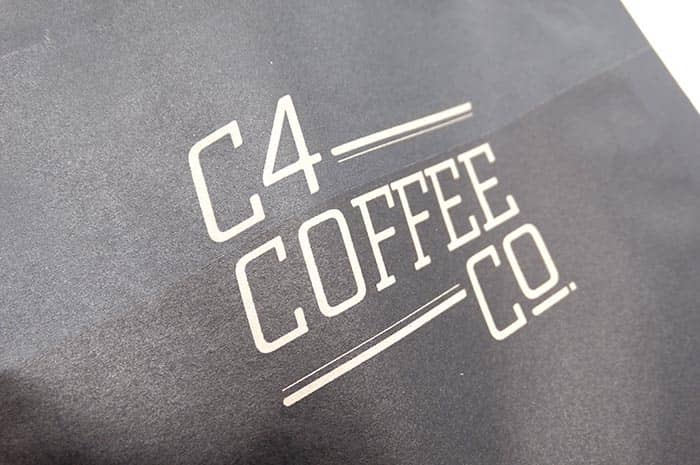

Complicated artwork design can be printed onto the surface of PLA+PBAT film with the highest standard of color consistency. We are offering gravure printing services up to 10 colors to finalize your great logo onto the packages.

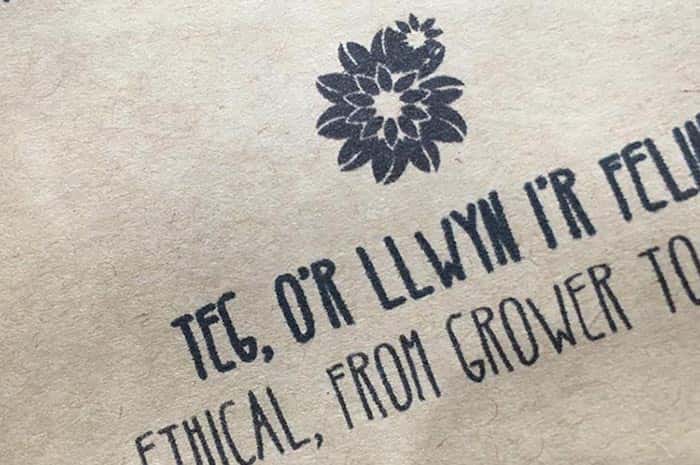

Water-based inks are available for the flexo printing onto PLA+PBAT film, which is able to present a better sustainability for the final packages. Just reach us if you have your artwork well finished for printing.

Complicated artwork design can be printed onto the surface of PLA+PBAT film with the highest standard of color consistency. We are offering gravure printing services up to 10 colors to finalize your great logo onto the packages.

Water-based inks are available for the flexo printing onto PLA+PBAT film, which is able to present a better sustainability for the final packages. Just reach us if you have your artwork well finished for printing.

Kraft paper, is able to be laminated with any other film substrate, nevertheless fossil-chemical films, such as BOPP film, PET film, PA film, LDPE film, or bioplastic film, like PLA film, and cellulose membrane. so various requirements can be met based on paper foil laminate. That’s why kraft paper is playing more and more important role in the packaging area.

Kraft paper degrade in short period in nature soil conditions, as of the plant fiber can be easily broken down into nutritions by the microorgaisms, which will enrich the soil in an optimized way.

Along with the sharps drops of the price for PLA and PBAT polymers, more and more products starts to shift to the compostable packages based on PLA+PBAT film.

Protecting the environment requires far-reaching projects, that’s why Brasilmoka is always looking for new ways to improve.

We have a plan in the pipeline that will help us further reduce emissions by shifting to a fleet of electric vans. Moreover, our dedication to innovation in packaging aims at reducing our environmental impact and promoting the use of state-of-the-art materials.