Tests under Laboratory Conditions

Anti-puncture Property

this cellulose film should not work great for anti-puncture purpose.

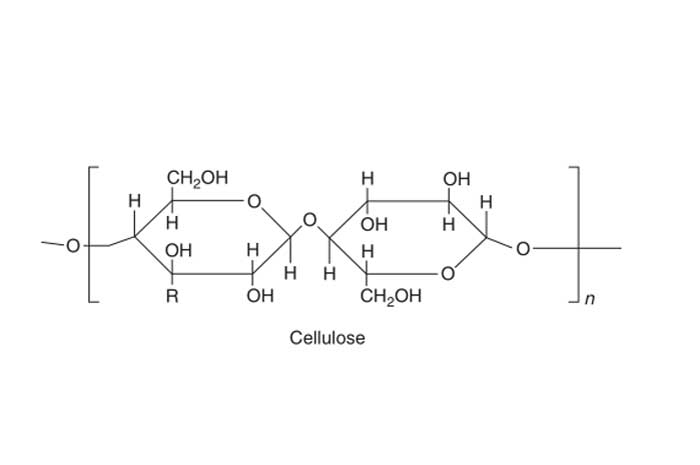

Cellulose film is considered one of the renewable and compostable packaging films with great potential applications. It is usually made from the fiber plants such as cotton, wood, hemp, etc, which are the same materials for producing paper. The raw materials enables the cellulose film to be 100% biodegradable, home compostable and fully recyclable. It even presents excellent degradation in seawater, which may help to reduce the plastic pollutions hereby caused by the traditonal fossil-chemicals polymer materials.

Here, in this post, we are going to guide our customers with a better understanding on this film, and try to assist the customers to achieve the ideal compostable packages for their lovely products.

Generally people mean the same thing by these two words, unless they are now being engaged in a serious scholar discussion. The word “cellophane” was formed from the first syllable of cellulose and the final syllable of diaphane (French word), which means transparent in English. Cellophane actually means the transparent film made of cellulose, and cellulose is a biomass which is mainly obtained from wood pulp and cotton. So when people talk about cellulose film, or paper, actually they mean cellophane, same thing, just different words. This case is quite like polyamide film, the formal chemical name, however people ofter call it nylon film.

Celloluse film is like film, with great transparency and film appearance. It is made of the same materials as paper, like cotton, wood pulp, hemp, etc, The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

Cellulose is mainly used to produce paperboard and paper, and small quantities of the cellulose is converted into film.

So, generally speaking, it should be called cellulose film or cellophane film. On the other hand, some people may just call it cellulose paper, due to different habits, this should not be wrongly understood it is plastic film.

Cellulose is very very moisture-sensitive compared to other traditional plastic film subtrate, such as polyester film, and polypropylene film. When some water is poured onto the surface, only several seconds pass, there will be significant distortion on the surface, just check the picture on the right. There will some water retained in the molecular structure of cellulose.

That water sensitive property not only limits the processing and converting of the cellulose film, but also for the stability of the sachet packaging when the products are well packed.

The cellophane production process involves five major steps

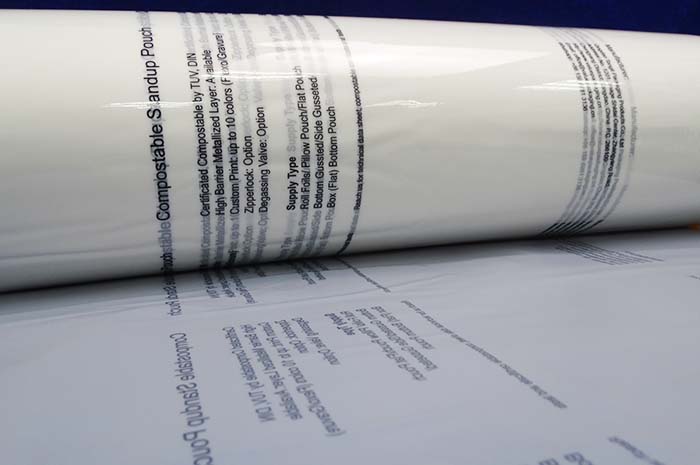

Complicated artwork design can be printed onto the outside surface or inner side of cellulose film with the highest standard of color consistency. We are offering gravure printing services up to 10 colors to finalize your great logo onto the packages, including matte lacquer coating.

Flexo printing can be well extended for printing on cellulose film and achieve the artwork in a vivid way.

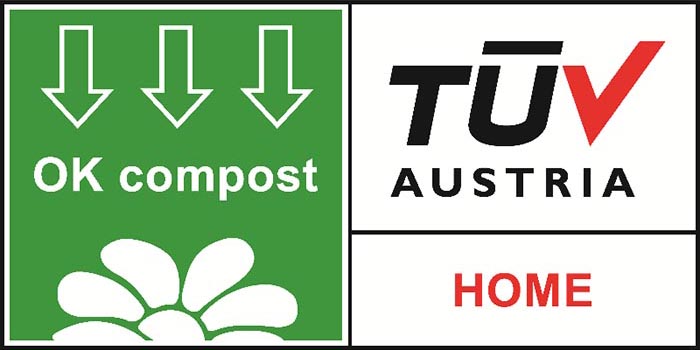

The regenerated cellulose membrane is certificated OK compostable under home and garden conditions by the well-known entity TUV.

This cellulose film is implemented to meet the requirements of FSC chain of custody certification standard.

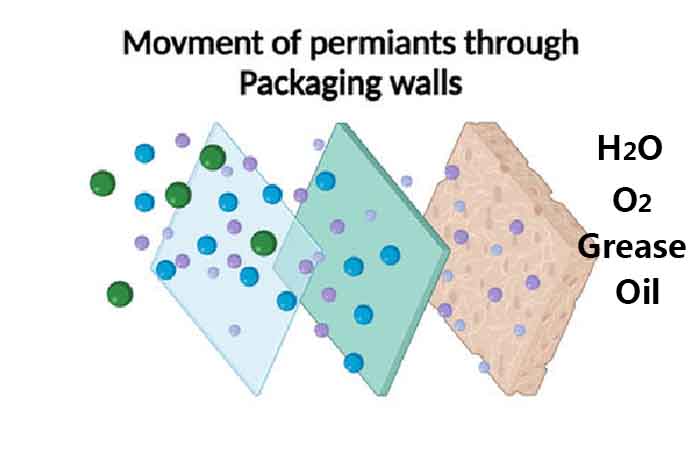

PVDC coating can be applied on single or both sides of the cellulose substrate, with improved barrier performance against oxygen and moisture. Along with the development of eco-friendly coating, PVA is now applied to achieve better sustainablity.

Based on cellulose film, Multilayer laminate can be achieved with other biodegradable substreate film, such as BOPLA membrane, Kraft Paper, Metallized Paper, PLA+PBAT biofilm, which are intended to achieve multi-functions to vairous products.

Complicated artwork design can be printed onto the surface of PLA+PBAT film with the highest standard of color consistency. We are offering gravure printing services up to 10 colors to finalize your great logo onto the packages.

Water-based inks are available for the flexo printing onto PLA+PBAT film, which is able to present a better sustainability for the final packages. Just reach us if you have your artwork well finished for printing.

The barrier performance of cellulose film will have to be improved when it is intended for some products that needs to be well protected for freshness or fragrance, such as coffee, nutritions, tea, snacks etc. In current technology, there are some ways to achieve this goal, including PVDC coating, Vacuum metallized, AlOx Coating, and further more PVA coating. Some of the craftsmanship can work togather to finalize premium performance.

this cellulose film should not work great for anti-puncture purpose.

Generally, the cellulose film will degrade entirely within 30~90 days under nature soil conditions. The biodegradation behavior just comes after kraft paper, which is even more versatile to moisture, sunlight and the activities of micro-organisms. So here we are going to make our own test with sample cellulose film buried in our landfield located in Qingdao, Shandong, north china. You may just learn more.

Along with the sharps drops of the price for PLA and PBAT polymers, more and more products starts to shift to the compostable packages based on PLA+PBAT film.

As environmental concerns grow, more and more companies are looking for eco-friendly and sustainable alternatives to traditional plastics. Protecting the environment requires far-reaching projects, that’s why Tongli is always looking for new ways to improve. Lucky for us, we now live in a world where it becomes easier to source sustainable materials, and now we are moving steadily to a more sustainable future.