BOPLA film, is short for biaxially orientated film made of poly lactic acid, which is the most common bio-based polymer at the large-scale commercialiaton. As lactic acid (short as LA) is usually derived from agricultural plants like cassava, potatoes and corns, so PLA polymer is considered as renewable film material.

Here, in this post, we are going to guide our customers with a better understanding on this film, and try to assist the customers to achieve the ideal compostable packages for their lovely products.

Biaxial orinetation is widely applied in the plastic film produce to achieve improved property for the final film products. When biaxial orientation is applied on a plastic film or sheet, the polymeric chains are modified more parallel to the plane of the film. The final films will present exceptional clarity, higher tensile strength, improved flexibility and toughness, batter barrier performance, and shrinkable property can be relatively achieved for some products, like PETG labels. So, BO-PLA film will be able to exhibit better performance for its application in the packaging areas.

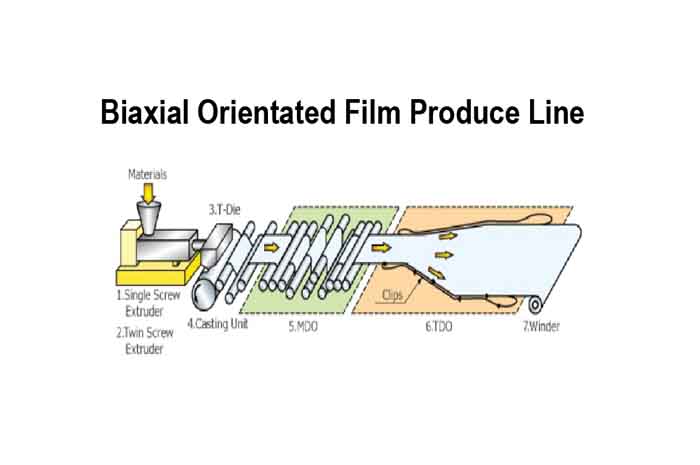

There are several steps included to make the BOPLA film on the biaxia orientation film produce line.

1. Blends of PLA polymer granules are supplemented to the hopper and melted under certain temperature.

2. The screw extruder passes the melted material to the T-die, to form an orginal film state

3. The film is cooled on the chilling roller after being released from T-die.

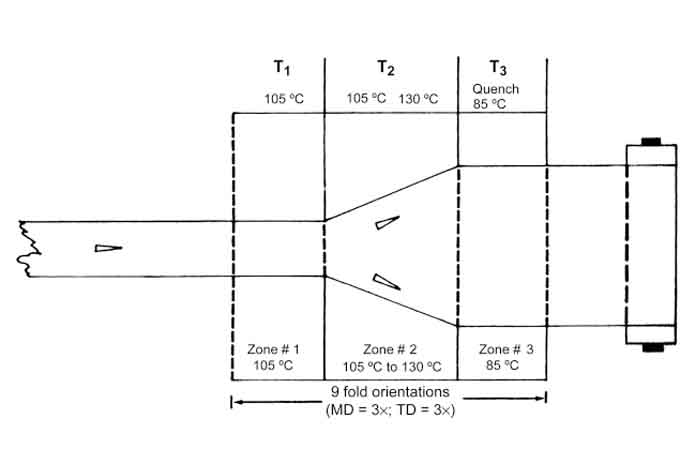

4. Machine direction orientation and transverse direction orientation are applied on the film stretching.

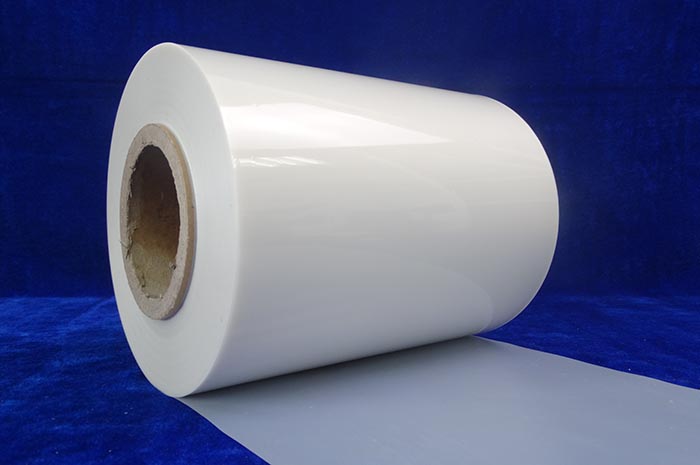

5. The film is rewound on to the rolls.

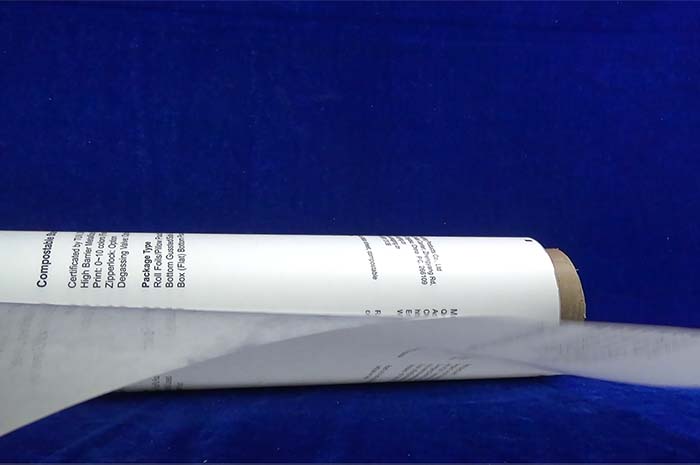

This film is ceritificated home compostable by third-inspection entity TUV, and you may get a sample film of our own for your own tests.

We hereby commit our BOPLA film is in compliance with FDA regulations, and thir-party inspection is available on customer’s request.

Complicated artwork design can be printed onto the outside surface or inner side of cellulose film with the highest standard of color consistency. We are offering gravure printing services up to 10 colors to finalize your great logo onto the packages, including matte lacquer coating.

Flexo printing can be well extended for printing on cellulose film and achieve the artwork in a vivid way.

Vacuum metallization enables the surface of BOPLA film deposited with a thin layer of aluminum atoms, which will largely improve the barrier performance of this film.

BOPLA film can be further laminated with kraft paper or PLA+PBAT film, to achieve multi-function foils, to meet the requirements of various proudcts in the consumer market.

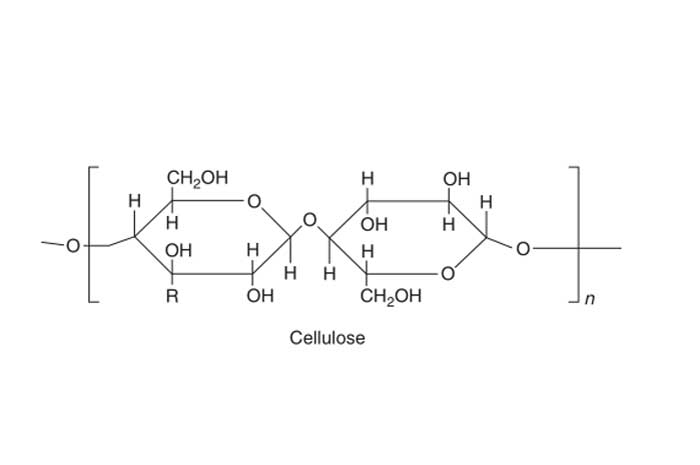

PVDC coating can be applied on single or both sides of the cellulose substrate, with improved barrier performance against oxygen and moisture. Along with the development of eco-friendly coating, PVA is now applied to achieve better sustainablity.

Based on cellulose film, Multilayer laminate can be achieved with other biodegradable substreate film, such as BOPLA membrane, Kraft Paper, Metallized Paper, PLA+PBAT biofilm, which are intended to achieve multi-functions to vairous products.

Here is heat seal property on both sides of BOPLA film, which enables the film being used as inner sealing layer for the multilayer flexible pouch. The sealing strength can be around 10~13N for foil laminate Kraft paper45g/BOPLA40um. As BOPLA film is too tough and right, which makes the sealed film easy to burst under outside pressure, so the BOPLA film can only be intended for the packages for light weight products, like spices, snacks less than 250g.

The biodegradation behavior of BOPLA film in soil conditions will be affected by the activites of the micro-organisms. Assimilation is the most important step in biodegradation process in which microorganisms use mainly carbon from monomers to produce CO2, energy and biomass under the aerobic conditions whereas CO2 and CH4 are formed under anaerobic conditions. Our test shows that it will surely take a longer time for BOPLA in degrade in soil conditions.

Even though BOPLA film and Cellophane are both considered as plant-based film materials, however they present quite different performance in the substrate, printing, converting and packaging applications, and that cause them to be intended for different areas. Here we are going to give a detailed comparison of these two bio-film, and hope it helps you to find the correct material.

Along with the sharps drops of the price for PLA and PBAT polymers, more and more products starts to shift to the compostable packages based on PLA+PBAT film.

Protecting the environment requires far-reaching projects, that’s why Brasilmoka is always looking for new ways to improve.

We have a plan in the pipeline that will help us further reduce emissions by shifting to a fleet of electric vans. Moreover, our dedication to innovation in packaging aims at reducing our environmental impact and promoting the use of state-of-the-art materials.