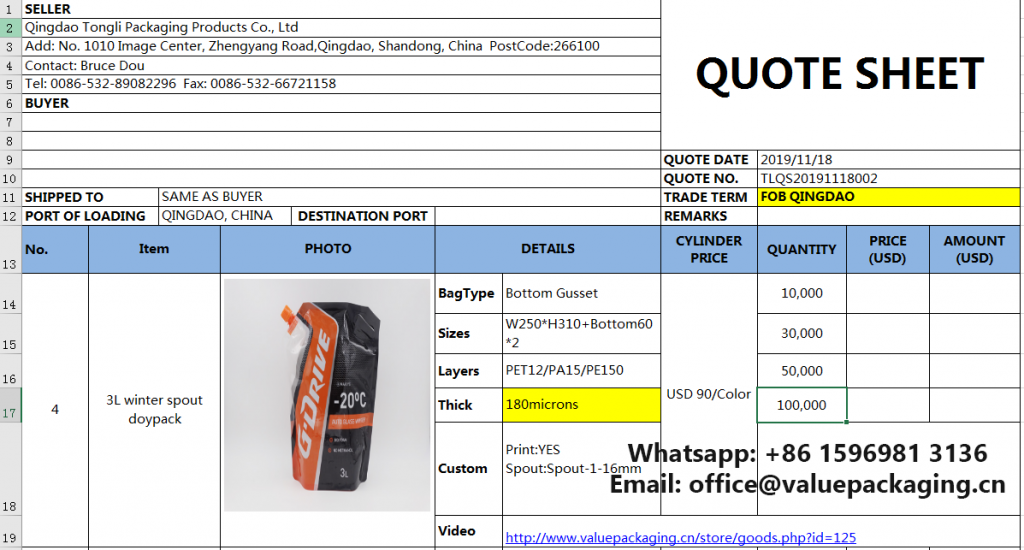

When some customers reach the flexible converter for the packages for their products, especially windshield washer fluids, liquid laundry detergent, fabric softner, liquid soap products, and the supplier may make the price quote against PET12/PA15/LDPE. What does that mean?

If the customer does not ever source the standup pouch package before, he may get confused with the price sheet, especially the layers PET12/PA15/LDPE150. He may wonder does this pouch meet his need?

Let’s give a brief introduce.

Pouch Foil Structure

For the standing pouches, it is seldom realized by single mono layer film, as different films have different properties, and the standup pouch will have to combine different properties to form the actual package that can be well used in our product packaging.

Usually the pouch foil consists of below layers

- Outside Print layer

- Middle barrier/support layer

- Inner seal layer

Sometimes, the middle layer may not be imperative, as some packages may not require superior barrier or stiff property, however in some other times, the middle layer can not be acheived by mono single layer.

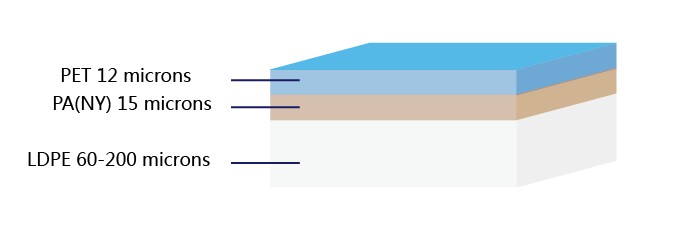

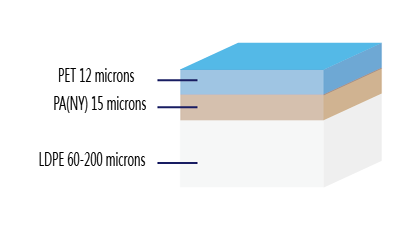

In this case, when it comes to PET12/PA15/LDPE, it actually means the foil structure should be as below

PET12, means polyester film 12 microns, equals to 48 gauge or 0.47mil, that works as outside print substrate film

PA15, means polyamide film 15 microns, that also have a more popular name-nylon (short as NY film), that works as middle support layer

LDPE150, means Low density polyethylene film 150 microns, that works as inner sealant layer, to seal the foil into standup pouch packages.

How this foil performs?

When the customer figure out what PET12/PA15/LDPE means, then he may come into the questions that matters much more to him.

How this foil performs?

Does this foil meet my need?

Is this foil the most cost-effective for my product package?

Let’s go over with each question.

Pouch Foil Strength

Pouch foil strength is the fundamental concern to decide a foil for a product package, nevertheless, the package should be strong protection for the inside products, espeically for liquid products. It should be a disaster if the liquid product package breaks during transport or distribution phase.

During our producing procedure, we perform impact test to check the strength for PET12/PA15/LDPE foil, you can watch this video test for PET12/PA15/LDPE150 foil that is intended for 1.25 liter liquid fertilizer.

Video

Pouch Foil Stiffness

The pouch fol stiffness affect the standup effect when the standup pouch packages are filled with liquid products. If the foil is not stiff and rigid enough, the standup pouch package may wrinkle or collapse with product filled.

At present, we are producing standup pouch package with PET12/PA15/LDPE in great stiffness, and when the product is filled into the package, it will present good standing effect on the shelf.

Of course, the thicker for the foil, the more stiff for the final package, however the cost increases at the same time. so we will have to evaluate the property and cost for our customers against their volume and expected effect. We will share more of our experience on the thickness for different volumes in future posts.

Temperature Resistance

For the final standup pouch package made from PET12/PA15/LDPE, it can well serve in wide range of temperature from -40

Hi Bruce

Hope you can give me some advise here .

I am hoping you can help me with some information about pillow pack machines . I am a packaging agent in South Africa.

1) What film construction do you recommend , to pack Wet tobacco , used in Hookah pipe – 50g for high speed packing ie 150 – 200 packs per minute ?

2) Do you recommend or not-recommend applying print on/in the seal area’s of the film ? Could print cause weak seals ?

I have a client that I supply laminated film , the film with no print in seal area’s can run machine at 150 sachets/minute ( sealing temp = 240degrees C , no problem.

However he recently launched a new line , this design has solid Black print with White print under black , with 100% ink coverage. At same temperature of 240deg C max speed he can achieve is 120 packs/minute . When trying to run at 150 per minute, the top and bottom seal become very weak or non existent.

As I said he is getting 150 sachets per minute out of the exact same construction film , the only difference is that the design has no print in the seal area’s .

The material construction we run is : Pet12/Alu foil7/Nylon15/ PE30mic

I did speak to someone at Huhtamaki here in South Africa , and they said the full ink coverage across the full web of the film will not cause seal problems if the construction is laminated layers whereby the ink is encapsulated between 2 films and has no contact with the sealing jaws .

I am a small packaging agency business of 25 years , so I would not like to lose this client because I cannot solve this problem.

Just out of interest , when I was being trained in packaging/printing 30 years ago , we were taught never to put print on/in seal area’s.

Bruce , has the time come to re-formulate his material construction ? If so what do you suggest . His product has aggressive properties , that’s why i went with the 4 layer construction in the beginning .

My client has just purchased a new machine that will run at 200 sachets/minute . If you send me your e-mail i will send you some pictures of the 50g sachets

I would really appreciate your expertise on this matter

Kind regards

David